Refractories Used In the Reverberatory Furnace

Date:2016-08-15 16:24 From:Zhengzhou Sunrise Refractory Author:admin

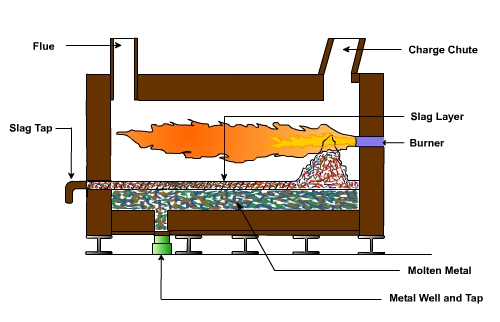

The reverberatory furnace is divided into two types: stationary and tilting. Commonly it is fueled with gas or heavy oil. Aluminum is usually smelted in a stationary reverberatory furnace.

The non-working layer is usually built with ceramic fiber blankets and fire clay insulation bricks. The working layer is usually built with fire clay bricks or high alumina refractory castable precast blocks, casted with high alumina refractory castables or rammed with plastic materials.

When the working conditions are different, the refractory materials are different. In general, it is built with 75% high alumina bricks or casted with 80% high alumina castables. When smelting high purity aluminum, the working layer is built with high quality mullite bricks, zircon bricks or corundum bricks. In order to resist the corrosion and penetration by molten aluminum, the aluminum outlet, aluminum tank and the lining is built with large silicon carbide bricks. The holding furnace and the treatment chamber for alloy material and solvents are built with substantially the same refractories with the reverberatory furnace.

When using liquid electrolytic aluminum as the raw material, aluminum liquid is sucked out with a siphon or by vacuum from an aluminum reduction cell. Then it is transported to the reverberatory furnace, poured from the charge port. After loading, while heating, the oxygen is blown into the bath for dehydrogenation. In generally, the lining of the siphon is insulated with refractory fiber-reinforced lightweight refractory castables or 0.8g/cm3 fire clay insulation bricks. The working layer is built with dense fire clay bricks or corundum bricks. The insulation layer is the same with that of the siphon, built with high quality fire clay bricks or high alumina bricks. Under normal operating conditions, the service life of the reverberatory furnace and the holding furnace is generally 2 to 5 years.