-

What Are the Molding Methods of Refractory Materials ?

have many molding methods, in addition to pressure molding method, contain the vibration molding, ramming molding, plastic molding, slip casting molding, casting molding, hot press molding and hot die casting molding, etc. 1. Vibration mold...

-

The Index Meaning Of Corundum Block

Bulk density: Bulk density is an indicator of weight for unit volume brick which means the weight is divided by the total volume. The weight can be weighed in the air directly, volume is a measure of the amount of space that an object takes...

-

Analysis on the Mechanical Properties of Thermal Insulation Materials

1, strength: refers to the material in the external force (load) under the action of no damage can withstand the maximum stress. According to the different ways of external force, the material strength of tensile, compression, bending (bend...

-

Refractory material production process

According to the degree of compactness and shape of the product, there are sintering method, casting method and melt injection method. Sintering method is the raw materials of raw materials pre-baked clinker, broken and sieved, and then by...

-

Zirconia hollow ball bricks and its use

To zirconia hollow ball as the main raw material made of heat insulation refractory products. (The main crystal phase of the brick is cubic zirconia (about 70% to 80% of the mineral phase), the refractoriness is greater than 2400 ℃, the p...

-

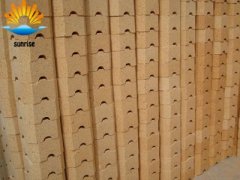

Characteristics of high alumina bricks

Characteristics of high alumina bricks A, refractoriness High alumina brick refractoriness than clay brick and semi-silica brick refractorance should be high, up to 1750 ~ 1790 ℃, are high refractories. B, load softening temperature Becau...

-

What is Magnesia Brick?

Magnesia brick contains more than 80%-85% Mg, and with periclase as the main mineral composition of the refractory material. The raw materials of magnesia brick are mainly magnesite, the basic component is MgCO2. According to different prod...

-

The molding methods of Refractory Materials

Refractory materials have many molding methods, in addition to pressure molding method, contain the vibration molding, ramming molding, plastic molding, slip casting molding, casting molding, hot press molding and hot die casting molding, e...

-

Magnesia Refractories Used In Induction Furnaces

According to the type of metal melting and smelting purposes, induction furnace lining can be built with acidic, neutral and basic refractories. The basic refractories are mainly composed of magnesia, lime, BeO, spinel and magnesium dolomit...

7 * 24 hours to serve you

If you need help, or if you want more product information, please contact us