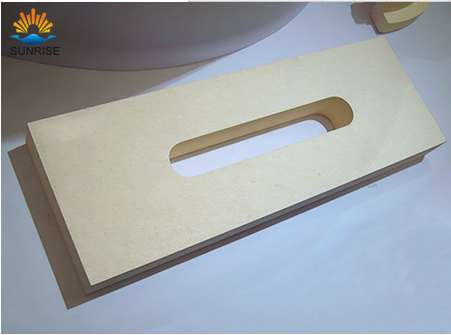

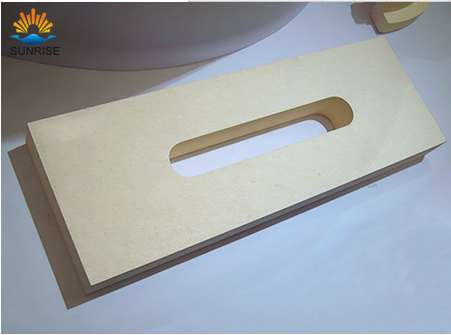

Corundum Brick using insulation technology can improve production efficiency

Date:2017-01-04 17:21 From:Zhengzhou Sunrise Refractory Author:admin

Corundum brick using insulation technology can reduce the useless heat loss of equipment, to enhance heat energy utilization efficiency, promote the kiln to develop to light-duty direction, and improve labor productivity.

As the thermal conductivity and strength of corundum brick are lower than the dense brick, its thermal shock resistance also decreased significantly. The porosity is the greater, the low is the more. Burning additives brick, especially adding into granular material is better than the thermal shock resistance of bubble lightweight refractory brick, however, a large number of standard size of corundum refractory brick (230mm × 120mm × 65mm) heated to 1300 ℃, only withstood 1-2 times heat exchange, it is difficult to adapt to the conditions of use. At the same time, it is confirmed that the initial formation of cooling cracks and broken part of the volume increases, in order to improve insulation performance of lightweight corundum brick.

General thermal equipment, starting from the conservation of energy and improve the working conditions, to take heat insulation is necessary. However, for certain equipment, needs to consider the pros and cons of insulation, not necessarily to take insulation measures. Therefore, it is necessary to proceed from reality, On the basis of mastering the characteristics of insulating refractory brick, correct selection of reasonable application of heat insulation brick, can achieve the desired purpose.

The principles of application corundum brick are:

(1) After thermal equipment adopting insulation measures, should not affect the life of the entire refractory masonry.

(2) For the continuous work of high-temperature furnace, the general large area of insulation is reasonable, can reduce heat loss. However, a small number of special parts, such as the open hearth furnace roof, when the insulation measures affect the life of the furnace roof, should not be insulated. For cyclical kilns, the heat loss is a major factor to the loss of heat, which is not necessary if the heat loss caused by an increase in the temperature of the masonry due to heat insulation exceeds the heat loss under non-insulated conditions. Therefore, the cyclical work of the furnace through the heat and heat loss of the specific calculation and decide whether to take insulation measures.

(3) As corundum brick has a higher porosity, in the use of corundum brick can not bear too much load, but also avoid contact with molten metal, slag and high temperature furnace dust.

(4) The heat insulation corundum brick's strength is lower. In the masonry insulation refractory brick, the brick joints and expansion joints should be properly arranged, so as to avoid squeezing the masonry expansion. Insulated corundum brick should not be subject to strong mechanical shock, impact and friction.

(5) The linear shrinkage of heat insulation corundum brick is big, the highest use temperature is lower about 100 ℃ than sintering temperature, can never exceed the allowed temperature to use.

As the thermal conductivity and strength of corundum brick are lower than the dense brick, its thermal shock resistance also decreased significantly. The porosity is the greater, the low is the more. Burning additives brick, especially adding into granular material is better than the thermal shock resistance of bubble lightweight refractory brick, however, a large number of standard size of corundum refractory brick (230mm × 120mm × 65mm) heated to 1300 ℃, only withstood 1-2 times heat exchange, it is difficult to adapt to the conditions of use. At the same time, it is confirmed that the initial formation of cooling cracks and broken part of the volume increases, in order to improve insulation performance of lightweight corundum brick.

General thermal equipment, starting from the conservation of energy and improve the working conditions, to take heat insulation is necessary. However, for certain equipment, needs to consider the pros and cons of insulation, not necessarily to take insulation measures. Therefore, it is necessary to proceed from reality, On the basis of mastering the characteristics of insulating refractory brick, correct selection of reasonable application of heat insulation brick, can achieve the desired purpose.

The principles of application corundum brick are:

(1) After thermal equipment adopting insulation measures, should not affect the life of the entire refractory masonry.

(2) For the continuous work of high-temperature furnace, the general large area of insulation is reasonable, can reduce heat loss. However, a small number of special parts, such as the open hearth furnace roof, when the insulation measures affect the life of the furnace roof, should not be insulated. For cyclical kilns, the heat loss is a major factor to the loss of heat, which is not necessary if the heat loss caused by an increase in the temperature of the masonry due to heat insulation exceeds the heat loss under non-insulated conditions. Therefore, the cyclical work of the furnace through the heat and heat loss of the specific calculation and decide whether to take insulation measures.

(3) As corundum brick has a higher porosity, in the use of corundum brick can not bear too much load, but also avoid contact with molten metal, slag and high temperature furnace dust.

(4) The heat insulation corundum brick's strength is lower. In the masonry insulation refractory brick, the brick joints and expansion joints should be properly arranged, so as to avoid squeezing the masonry expansion. Insulated corundum brick should not be subject to strong mechanical shock, impact and friction.

(5) The linear shrinkage of heat insulation corundum brick is big, the highest use temperature is lower about 100 ℃ than sintering temperature, can never exceed the allowed temperature to use.