Raw Material and Process Flow of Fused Zirconium Corundum Brick

Date:2019-08-27 17:03 From:Zhengzhou Sunrise Refractory Author:admin

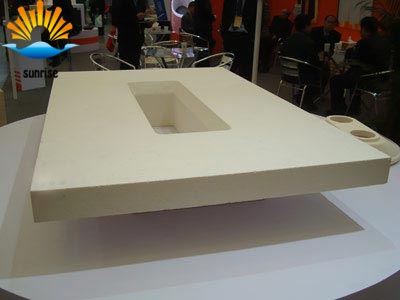

The fused zirconia corundum brick is mainly composed of zircon and industrial alumina, and a small amount of zirconium-rich sand (in order to increase the content of ZrO2) and soda ash (fused, Na2O can inhibit the formation of mullite and promote mullite). Thermal decomposition and borax (refining, improving the properties of the glass phase, preventing cracking of the casting).

There are two kinds of reduction melting methods and oxidative melting methods depending on the atmosphere at the time of melting. The reduction method is to insert the graphite electrode directly into the melt to make the solution carburize (carbon content 0.03%~0.19%), and reduce the iron and titanium oxide impurities in the material to low-valent oxide, thereby reducing the glass phase oozing. Temperature (exudation temperature is about 1200~1330 ° C). The oxidation method requires a large amount of power, the graphite electrode is not in contact with the molten metal, the carbon does not penetrate, and oxygen is blown in at an appropriate time, which can make the reducing substance become an oxidizing substance and can also remove the pollution caused by the graphite electrode in the molten metal. . The bricks are light beige with low carbon content (0.005% to 0.02%). The number of glass phases is small and the oozing temperature is high (1380~1410 °C or higher).

If you have interested in our fused zirconia corundum brick, please connected with us, and you will get more information about fused zirconia corundum brick for sales.