Matters Needing Attention in The Heating of Fused Zirconium Corundum Pool Wall Brick

Date:2019-08-19 15:53 From:Zhengzhou Sunrise Refractory Author:admin

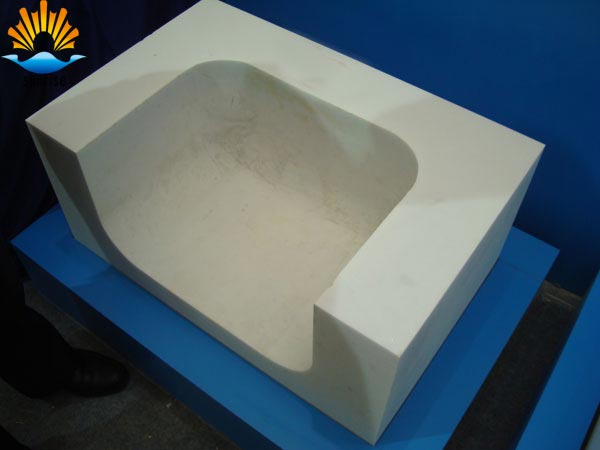

1. Characteristics of fused zirconium corundum brick

There are many domestic manufacturers of fused refractory materials for glass kiln, and the product quality level and price difference are also very large. Many domestic manufacturers have great room for improvement in appearance quality, composition design, casting process and dimensional accuracy. The quality directly affects the life of the pool wall, especially the crystal phase structure, glass phase content and processing accuracy of the brick.

Due to the compact structure and low porosity, the fused refractory material has a high Young's modulus and a high brittleness below 800 °C. The cold compressive strength is very large, greater than 350 MPa, but the tensile strength is only about 20 MPa. In the case of impact and uneven heating, when the tensile stress caused by the temperature difference is too large and the volume changes too fast, there is no pores to act as a buffer, and it is easy to burst.

2. Precautions when warming up

During the heating process of the fused zirconia corundum pool brick, when the temperature is between 0 and 1100 °C, the brick gradually expands linearly with the increase of temperature. The expansion amount is about 0.8% and the temperature is between 1100 and 1200 °C. At the time, the monoclinic ZrO2 in the brick body is transformed into the tetragonal ZrO2, and the volume of the brick is contracted with the change of volume. The bus expansion rate is reduced from about 0.8% to about 0.6%; when the temperature is higher than 1200 °C As the temperature rises, the bricks begin to expand again; when the temperature is below 1600 °C, the overall expansion characteristics of the brick wall bricks are not large, and the average expansion coefficient is about 7×10^-6/°C.

During the kiln, the maximum tensile stress occurs in the non-insulated area above the brick wall, close to the cold side of the brick, and increases with increasing temperature until the temperature is stable. When the cooling wind is started, the tensile stress of the brick body has a short-term peak. Therefore, when the stress is small, that is, when the temperature of the kiln is lower than 700 ° C, the wind is gradually increased, and the number of cracks generated is relatively small. Because of the reason of the lower layer insulation, the force distribution of the stress in the longitudinal direction of the pool wall is larger than that in the vertical and thickness directions of the pool wall, and often exceeds the tensile strength limit of the brick. Therefore, longitudinal cracks generally appear in the wall brick during the kiln process. Generally, it occurs in a period of time after the cooling air is turned on and the temperature of the kiln is 950~1200 °C. The crack develops to the thickness and vertical direction of the brick. When the temperature of the kiln is 900~1200 °C, the heating rate should not be too fast. The requirement is no more than 15 ° C / h. When the internal temperature of the brick body is greater than 1000 ° C, the brick body shows a plastic body, which can absorb the generated stress and crack, and the crack is also closed. Cracks generated in the kiln do not spread to the hot and insulated areas of the brick.

Due to the design and bricklaying, the expansion joints or partial seams between the brick walls are not tightly attached. During the roasting process, the heat is scattered at the straight seams, the temperature of the brick edges rises, and the tensile stress is from the bricks. When the outer surface moves toward the inside and the stress changes, there is a danger of horizontal cracking. Therefore, the pre-arrangement and precision machining of the wall bricks are also very important.