Sunrise Refractory High Quality Chrome Corundum Brick Hot Sell

Date:2019-12-02 16:22 From:Zhengzhou Sunrise Refractory Author:admin

Zirconium corundum bricks are smelted from alumina and zirconia in an electric arc furnace at a high temperature above 2000 ° C. Tough texture, dense structure and high strength. The main mineral phase of zirconium corundum is eutectic formed by a-alumina and alumina-zirconia. The melting point of alumina is 2050 ° C, and the melting point of zirconia is 2690 ° C. When the alumina content is 42.6% and the temperature is 1710 ° C, it is the eutectic point of alumina and zirconia.

After the composition is determined, when the temperature is above the liquidus of the corresponding composition, changing its temperature will not cause the appearance of a new phase. When the temperature drops to the liquidus of the corresponding component, the crystalline phase begins to precipitate, and the liquid composition changes along the liquidus to the eutectic point. When the temperature reaches the eutectic point, crystalline alumina and zirconia eutectic phases are simultaneously precipitated in proportion to the eutectic point composition. When the zirconium corundum melt cools, crystals begin to form. The crystal size is generally achieved by controlling the crystal growth rate, that is, by adopting a rapid cooling (supercooling) method. In order to ensure the quality of zirconium corundum, in addition to reasonable selection of smelting parameters and processes, cooling processes and processing techniques, appropriate additives are selected to reduce the silicon oxide content in zirconium corundum bricks, so that alumina and zirconia eutectic and have a uniform structure. The key to zirconium corundum brick production.

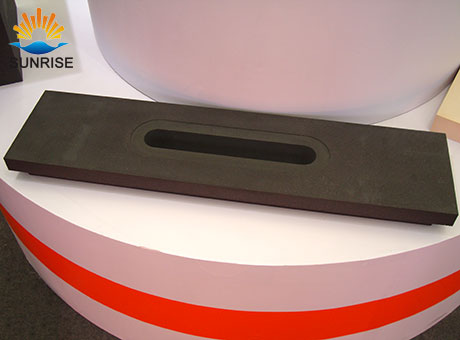

The high-purity corundum brick produced by sunrise Refractory Technology Co., Ltd. uses fused white alumina as the main raw material. The product structure is dense and high-temperature strength, and has outstanding corrosion resistance and wear resistance, strong stability, not affected by H2, The effects of CO and other reducing gases are widely used in various high-temperature electric furnace linings and high-temperature electric furnace accessories, ceramics, electronics, metallurgy and other industries in medium and high temperature parts.

Corundum mullite bricks are made of high-purity corundum and high-quality mullite through high pressure molding and high temperature firing.

The product has the characteristics of high temperature resistance, corrosion resistance, oxidation resistance, good thermal stability, and low linear change rate. It is mainly used in the petrochemical industry, large and medium-sized synthetic ammonia gasification furnaces and magnetic material gas furnace materials, and high-temperature industrial furnace supporting facilities materials. Wait. If you are interested in our refractory bricks, please contact sunrise Refractories for more details.