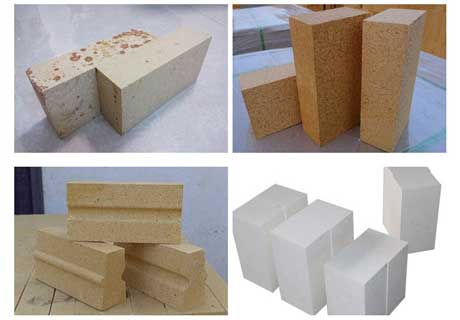

Product characteristics of Sunrise Refractory high alumina brick

Date:2019-11-14 14:10 From:Zhengzhou Sunrise Refractory Author:admin

Sunrise Refractory Co., ltd. is a professional manufacturer and supplier of refractory products in China's refractory base. Toady Sunrise Refractory mainly introduce the characteristics of High alumina bricks.

1.Refractoriness

The high alumina bricks have higher refractoriness than clay bricks and semi-silica bricks, reaching 1750~1790 °C, which is a high-grade refractory material. The degree of refractoriness is mainly affected by the content and type and quantity of AL2O3, and the refractoriness increases with the increase of AL2O3 content.

2. Load softening temperature

Because the high aluminum product has high AL2O3, low impurity content and less fusible glass body, the load softening temperature is higher than clay brick, but the mullite crystal does not form a network structure, so the load softening temperature is still not high. .

3. Thermal conductivity

High alumina bricks have better thermal conductivity than clay bricks. The reason is that the glass phase with low thermal conductivity in high aluminum products is less, and the number of mullite and corundum crystals with better thermal conductivity is increased, which improves the thermal conductivity of the product.

4. Resistance to thermal shock stability

The thermal shock resistance of high alumina bricks is between clay products and silicon products. The water cooling cycle at 850 °C is only 3 to 5 times. This is mainly due to the fact that the thermal expansion of corundum is higher than that of mullite, and there is no crystal transformation. At present, the thermal shock resistance of the product can be improved by improving the granular structure of the product, reducing the content of the fine powder, and increasing the critical particle size and particle gradation of the clinker.

5. Slag resistance

There are many AL2O3 in high alumina bricks, close to neutral refractories. You can resist the erosion of acid slag and alkaline slag. Because of the SiO2 content, the ability to resist alkaline slag is weaker than the slag resistance. In addition, the slag resistance of high alumina products is also related to the stability of the product in the slag. In general, articles having a lower porosity have a higher slag resistance after high pressure molding and high temperature firing.