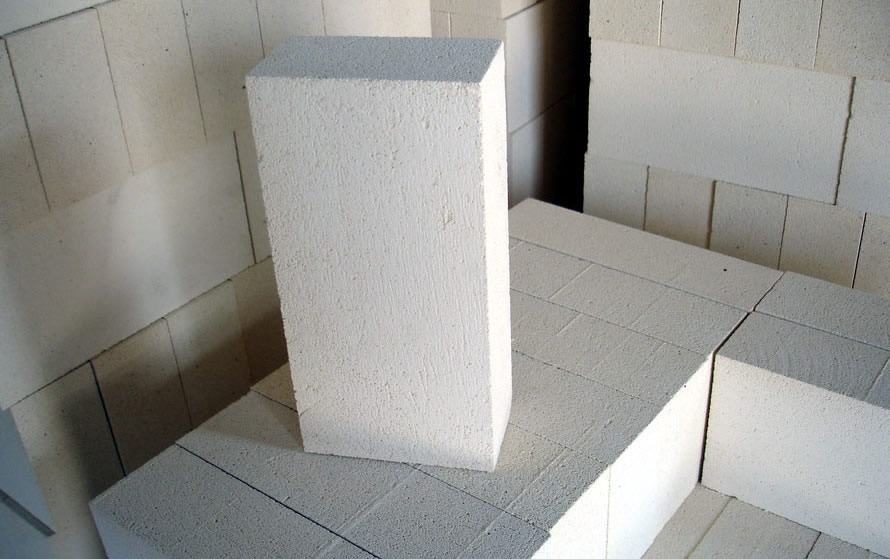

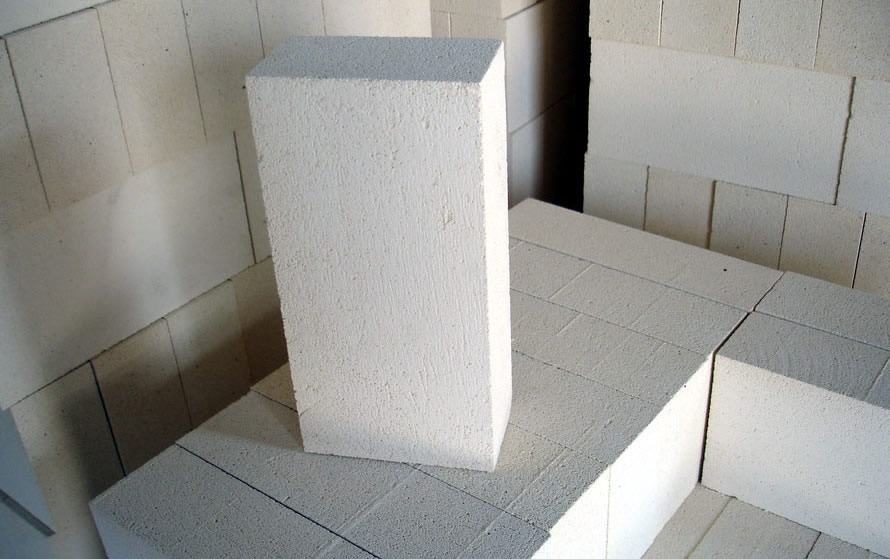

Analysis on the casting method of corundum bricks

Date:2019-01-04 16:24 From:Zhengzhou Sunrise Refractory Author:admin

1, no shrinkage casting

The shrinkage hole is concentrated in a certain area, and after annealing, the diamond is cut off by a diamond saw, the remaining useful parts are uniform, the structure is dense, and the average bulk density is close to the theoretical density; the other is the cutting leg method: reducing the cutting area Starting from casting the casting into an "L" shape, the majority of the shrinkage cavities are concentrated on the smaller leg of the "L". The volume of the leg accounts for 60% of the total volume of the casting. The entire casting is buried in the insulating material during annealing. Inside, and keep it tilted to make the shrinkage hole concentrate on the leg.

2, corundum brick inclined casting method

The inclined casting method is to cast the mold at an angle before casting, and the riser is placed at one end of the mold for casting, so that a dense region can be obtained in the T portion, and a higher mold can be used in the T direction. The accuracy. Therefore, when the wall of the pool is built with such a casting, the height can be utilized.

3, corundum brick ordinary casting method

3, corundum brick ordinary casting method

The bricks cast in this way are cheaper, and are mostly used in the upper structure of the kiln, clarifying the walls of the pool, and the like. The casting is cast by ordinary riser, and the riser is removed in the hot state. The section is divided into two parts, one part is solidified first and the crystal is fine, the area accounts for 40%-50% of the thickness of the casting, and the other part is post-cured. Shrinkage and coarse crystallization.

The shrinkage hole is concentrated in a certain area, and after annealing, the diamond is cut off by a diamond saw, the remaining useful parts are uniform, the structure is dense, and the average bulk density is close to the theoretical density; the other is the cutting leg method: reducing the cutting area Starting from casting the casting into an "L" shape, the majority of the shrinkage cavities are concentrated on the smaller leg of the "L". The volume of the leg accounts for 60% of the total volume of the casting. The entire casting is buried in the insulating material during annealing. Inside, and keep it tilted to make the shrinkage hole concentrate on the leg.

2, corundum brick inclined casting method

The inclined casting method is to cast the mold at an angle before casting, and the riser is placed at one end of the mold for casting, so that a dense region can be obtained in the T portion, and a higher mold can be used in the T direction. The accuracy. Therefore, when the wall of the pool is built with such a casting, the height can be utilized.

The bricks cast in this way are cheaper, and are mostly used in the upper structure of the kiln, clarifying the walls of the pool, and the like. The casting is cast by ordinary riser, and the riser is removed in the hot state. The section is divided into two parts, one part is solidified first and the crystal is fine, the area accounts for 40%-50% of the thickness of the casting, and the other part is post-cured. Shrinkage and coarse crystallization.